Torque is defined as the measurement of resistance to turning or rotating. It tends to twist a body about an axis of rotation. A common example of this would be tightening a threaded retainer such as a nut, bolt or screw. Measuring torque is one of the most common ways to help assure that a threaded retainer has been properly fastened.

When tightening a threaded fastener, torque is applied in three distinct areas, the head, the bearing surface and the clamp load. About 50 percent of the measured torque is used in overcoming bearing friction. This is the friction between the bearing surface of the bolt head, screw head or nut face and the base material or washer (the surface on which the fastener is rotating). Approximately 40 percent of the applied torque is used in overcoming thread friction. This leaves only about 10 percent of the applied torque to develop a useful clamp load (the force which holds a joint together). This means that friction can account for as much as 90 percent of the applied torque on a fastener.

TORQUE WRENCHES

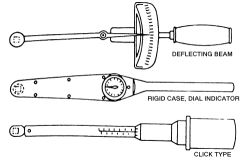

See Figures 1, 2 and 3

|  |

Fig. Fig. 1: Various styles of torque wrenches are usually available at your local automotive supply store

|  |

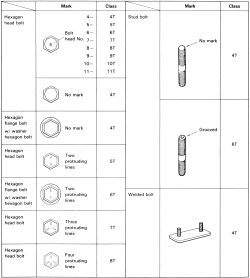

Fig. Fig. 2: Determining bolt strength of metric fasteners-NOTE: this is a typical bolt marking system, but there is not a worldwide standard

|  |

Fig. Fig. 3: Typical bolt torques for metric fasteners-WARNING: use only as a guide

In most applications, a torque wrench can be used to assure proper installation of a fastener. Torque wrenches come in various designs and most automotive supply stores will carry a variety to suit your needs. A torque wrench should be used any time we supply a specific torque value for a fastener. A torque wrench can also be used if you are following the general guidelines in the accompanying charts. Keep in mind that because there is no worldwide standardization of fasteners, the charts are a general guideline and should be used with caution. Again, the general rule of "if you are using the right tool for the job, you should not have to strain to tighten a fastener'' applies here.

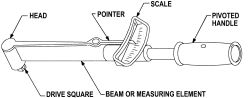

Beam TypeSee Figure 4

|  |

Fig. Fig. 4: Example of a beam type torque wrench

The beam type torque wrench is one of the most popular types. It consists of a pointer attached to the head that runs the length of the flexible beam (shaft) to a scale located near the handle. As the wrench is pulled, the beam bends and the pointer indicates the torque using the scale.

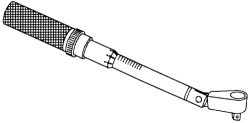

Click (Breakaway) TypeSee Figure 5

|  |

Fig. Fig. 5: A click type or breakaway torque wrench-note this one has a pivoting head

Another popular design of torque wrench is the click type. To use the click type wrench you pre-adjust it to a torque setting. Once the torque is reached, the wrench has a reflex signaling feature that causes a momentary breakaway of the torque wrench body, sending an impulse to the operator's hand.

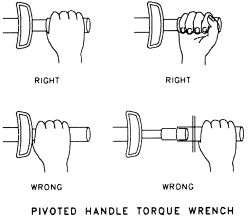

Pivot Head TypeSee Figures 5 and 6

|  |

Fig. Fig. 6: Torque wrenches with pivoting heads must be grasped and used properly to prevent an incorrect reading

Some torque wrenches (usually of the click type) may be equipped with a pivot head which can allow it to be used in areas of limited access. BUT, it must be used properly. To hold a pivot head wrench, grasp the handle lightly, and as you pull on the handle, it should be floated on the pivot point. If the handle comes in contact with the yoke extension during the process of pulling, there is a very good chance the torque readings will be inaccurate because this could alter the wrench loading point. The design of the handle is usually such as to make it inconvenient to deliberately misuse the wrench.

It should be mentioned that the use of any U-joint, wobble or extension will have an effect on the torque readings, no matter what type of wrench you are using. For the most accurate readings, install the socket directly on the wrench driver. If necessary, straight extensions (which hold a socket directly under the wrench driver) will have the least effect on the torque reading. Avoid any extension that alters the length of the wrench from the handle to the head/driving point (such as a crow's foot). U-joint or Wobble extensions can greatly affect the readings; avoid their use at all times.

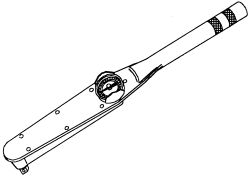

Rigid Case (Direct Reading)See Figure 7

|  |

Fig. Fig. 7: The rigid case (direct reading) torque wrench uses a dial indicator to show torque

A rigid case or direct reading torque wrench is equipped with a dial indicator to show torque values. One advantage of these wrenches is that they can be held at any position on the wrench without affecting accuracy. These wrenches are often preferred because they tend to be compact, easy to read and have a great degree of accuracy.

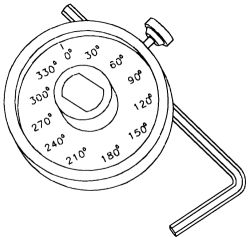

TORQUE ANGLE METERS

See Figure 8

|  |

Fig. Fig. 8: Some specifications require the use of a torque angle meter (mechanical protractor)

Because the frictional characteristics of each fastener or threaded hole will vary, clamp loads which are based strictly on torque will vary as well. In most applications, this variance is not significant enough to cause worry. But, in certain applications, a manufacturer's engineers may determine that more precise clamp loads are necessary (such is the case with many aluminum cylinder heads). In these cases, a torque angle method of installation would be specified. When installing fasteners which are torque angle tightened, a predetermined seating torque and standard torque wrench are usually used first to remove any compliance from the joint. The fastener is then tightened the specified additional portion of a turn measured in degrees. A torque angle gauge (mechanical protractor) is used for these applications.