PRECAUTIONS

On models with an airbag, wait at least 90 seconds from the time that the ignition switch is turned to the LOCK position and the battery is disconnected before performing any further work.

Always use caution when working on or near the battery. Never allow a tool to bridge the gap between the negative and positive battery terminals. Also, be careful not to allow a tool to provide a ground between the positive cable/terminal and any metal component on the vehicle. Either of these conditions will cause a short circuit, leading to sparks and possible personal injury.

Do not smoke, have an open flame or create sparks near a battery; the gases contained in the battery are very explosive and, if ignited, could cause severe injury or death.

All batteries, regardless of type, should be carefully secured by a battery hold-down device. If this is not done, the battery terminals or casing may crack from stress applied to the battery during vehicle operation. A battery which is not secured may allow acid to leak out, making it discharge faster; such leaking corrosive acid can also eat away at components under the hood.

Always visually inspect the battery case for cracks, leakage and corrosion. A white corrosive substance on the battery case or on nearby components would indicate a leaking or cracked battery. If the battery is cracked, it should be replaced immediately.

GENERAL MAINTENANCE

See Figure 1

A battery that is not sealed must be checked periodically for electrolyte level. You cannot add water to a sealed maintenance-free battery (though not all maintenance-free batteries are sealed); however, a sealed battery must also be checked for proper electrolyte level, as indicated by the color of the built-in hydrometer "eye.''

|  |

Fig. Fig. 1: A typical location for the built-in hydrometer on maintenance-free batteries

Always keep the battery cables and terminals free of corrosion. Check these components about once a year. Refer to the removal, installation and cleaning procedures outlined in this section.

Keep the top of the battery clean, as a film of dirt can help completely discharge a battery that is not used for long periods. A solution of baking soda and water may be used for cleaning, but be careful to flush this off with clear water. DO NOT let any of the solution into the filler holes. Baking soda neutralizes battery acid and will de-activate a battery cell.

Batteries in vehicles which are not operated on a regular basis can fall victim to parasitic loads (small current drains which are constantly drawing current from the battery). Normal parasitic loads may drain a battery on a vehicle that is in storage and not used for 6-8 weeks. Vehicles that have additional accessories such as a cellular phone, an alarm system or other devices that increase parasitic load may discharge a battery sooner. If the vehicle is to be stored for 6-8 weeks in a secure area and the alarm system, if present, is not necessary, the negative battery cable should be disconnected at the onset of storage to protect the battery charge.

Remember that constantly discharging and recharging will shorten battery life. Take care not to allow a battery to be needlessly discharged.

BATTERY FLUID

Check the battery electrolyte level at least once a month, or more often in hot weather or during periods of extended vehicle operation. On non-sealed batteries, the level can be checked either through the case on translucent batteries or by removing the cell caps on opaque-cased types. The electrolyte level in each cell should be kept filled to the split ring inside each cell, or the line marked on the outside of the case.

If the level is low, add only distilled water through the opening until the level is correct. Each cell is separate from the others, so each must be checked and filled individually. Distilled water should be used, because the chemicals and minerals found in most drinking water are harmful to the battery and could significantly shorten its life.

If water is added in freezing weather, the vehicle should be driven several miles to allow the water to mix with the electrolyte. Otherwise, the battery could freeze.

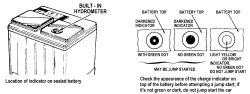

Although some maintenance-free batteries have removable cell caps for access to the electrolyte, the electrolyte condition and level on all sealed maintenance-free batteries must be checked using the built-in hydrometer "eye.'' The exact type of eye varies between battery manufacturers, but most apply a sticker to the battery itself explaining the possible readings. When in doubt, refer to the battery manufacturer's instructions to interpret battery condition using the built-in hydrometer.

Although the readings from built-in hydrometers found in sealed batteries may vary, a green eye usually indicates a properly charged battery with sufficient fluid level. A dark eye is normally an indicator of a battery with sufficient fluid, but one which may be low in charge. And a light or yellow eye is usually an indication that electrolyte supply has dropped below the necessary level for battery (and hydrometer) operation. In this last case, sealed batteries with an insufficient electrolyte level must usually be discarded.

Checking the Specific GravitySee Figure 2, 3, 4 and 5

A hydrometer is required to check the specific gravity on all batteries that are not maintenance-free. On batteries that are maintenance-free, the specific gravity is checked by observing the built-in hydrometer "eye" on the top of the battery case. Check with your battery's manufacturer for proper interpretation of its built-in hydrometer readings.

|  |

Fig. Fig. 2: On non-maintenance-free batteries, the fluid level can be checked through the case on translucent models; the cell caps must be removed on other models

|  |

Fig. Fig. 3: If the fluid level is low, add only distilled water through the opening until the level is correct

|  |

Fig. Fig. 4: Check the specific gravity of the battery's electrolyte with a hydrometer

|  |

Fig. Fig. 5: A typical sealed (maintenance-free) battery with a built-in hydrometer-NOTE that the hydrometer eye may vary between battery manufacturers; always refer to the battery's label

The fluid (sulfuric acid solution) contained in the battery cells will tell you many things about the condition of the battery. Because the cell plates must be kept submerged below the fluid level in order to operate, maintaining the fluid level is extremely important. And, because the specific gravity of the acid is an indication of electrical charge, testing the fluid can be an aid in determining if the battery must be replaced. A battery in a vehicle with a properly operating charging system should require little maintenance, but careful, periodic inspection should reveal problems before they leave you stranded.

As stated earlier, the specific gravity of a battery's electrolyte level can be used as an indication of battery charge. At least once a year, check the specific gravity of the battery. It should be between 1.20 and 1.26 on the gravity scale. Most auto supply stores carry a variety of inexpensive battery testing hydrometers. These can be used on any non-sealed battery to test the specific gravity in each cell.

The battery testing hydrometer has a squeeze bulb at one end and a nozzle at the other. Battery electrolyte is sucked into the hydrometer until the float is lifted from its seat. The specific gravity is then read by noting the position of the float. If gravity is low in one or more cells, the battery should be slowly charged and checked again to see if the gravity has come up. Generally, if after charging, the specific gravity between any two cells varies more than 50 points (0.50), the battery should be replaced, as it can no longer produce sufficient voltage to guarantee proper operation.

CABLES

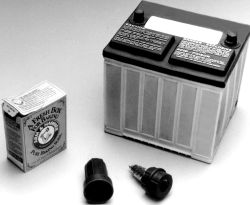

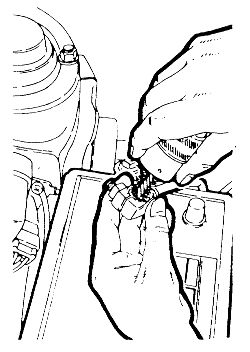

See Figures 6, 7, 8, 9 and 10

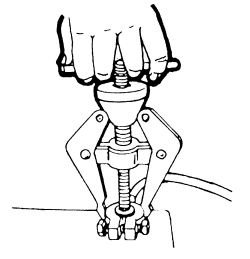

Once a year (or as necessary), the battery terminals and the cable clamps should be cleaned. Loosen the clamps and remove the cables, negative cable first. On batteries with posts on top, the use of a puller specially made for this purpose is recommended. These are inexpensive and available in most auto parts stores. Side terminal battery cables are secured with a small bolt.

Clean the cable clamps and the battery terminal with a wire brush, until all corrosion, grease, etc., is removed and the metal is shiny. It is especially important to clean the inside of the clamp thoroughly (an old knife is useful here), since a small deposit of foreign material or oxidation there will prevent a sound electrical connection and inhibit either starting or charging. Special tools are available for cleaning these parts, one type for conventional top post batteries and another type for side terminal batteries. It is also a good idea to apply some dielectric grease to the terminal, as this will aid in the prevention of corrosion.

After the clamps and terminals are clean, reinstall the cables, negative cable last; DO NOT hammer the clamps onto battery posts. Tighten the clamps securely, but do not distort them. Give the clamps and terminals a thin external coating of grease after installation, to retard corrosion.

Check the cables at the same time that the terminals are cleaned. If the cable insulation is cracked or broken, or if the ends are frayed, the cable should be replaced with a new cable of the same length and gauge.

|  |

Fig. Fig. 6: Maintenance is performed with household items and with special tools like this post cleaner

|  |

Fig. Fig. 7: The underside of this special battery tool has a wire brush to clean post terminals

|  |

Fig. Fig. 8: Place the tool over the battery posts and twist to clean until the metal is shiny

|  |

Fig. Fig. 9: A special tool is available to pull the clamp from the post

|  |

Fig. Fig. 10: The cable ends should be cleaned as well

CHARGING

A battery should be charged at a slow rate to keep the plates inside from getting too hot. However, if some maintenance-free batteries are allowed to discharge until they are almost "dead,'' they may have to be charged at a high rate to bring them back to "life.'' Always follow the charger manufacturer's instructions on charging the battery.

REPLACEMENT

When it becomes necessary to replace the battery, select one with an amperage rating equal to or greater than the battery originally installed. Deterioration and just plain aging of the battery cables, starter motor, and associated wires makes the battery's job harder in successive years. The slow increase in electrical resistance over time makes it prudent to install a new battery with a greater capacity than the old.