OPERATION

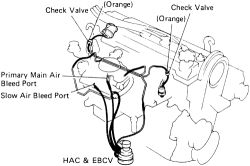

See Figure 1

This system is used on the 4A-FE engines only.

As altitude increases, air density decreases. This causes the air/fuel mixture to become richer (the same amount of fuel is mixing with less air). The high altitude compensation (HAC) system insures a proper air/fuel mixture by supplying additional air to the primary low and high speed circuits of the carburetor and advancing the ignition timing to improve driveability at altitudes above 3,930 feet (1,200 m). At altitudes below 2,570 feet (783 m), normal operation is resumed.

|  |

Fig. Fig. 1: Components of the High Altitude Compensation (HAC) system

TESTING HAC Valve

- Visually check and clean the air filter in the HAC valve.

-

Check the HAC valve as follows:

- Above 3,930 ft. (1,200 m), blow into any one of the two ports on top of the HAC valve with the engine idling and check that the HAC valve is open (air flows through the bottom of the valve).

- Below 2,570 ft. (783 m), blow into any one of the two ports on top of the HAC valve with the engine idling and check that the HAC valve is closed (no air flow through the bottom of the valve).

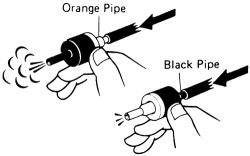

See Figure 2

- Check the valve by blowing air into each pipe:

- Check that air flows from the orange pipe to the black pipe.

|  |

Fig. Fig. 2: Air should flow from the orange pipe to the black pipe, but not from the black pipe to the orange pipe

- Check that air does not flow from the black pipe to the orange pipe.

- Remove the distributor cap and rotor.

- Plug one port of the sub-diaphragm. Using a hand-held vacuum pump, apply vacuum to the diaphragm, checking that the vacuum advance moves when the vacuum is applied.

- Reinstall the rotor and distributor cap.