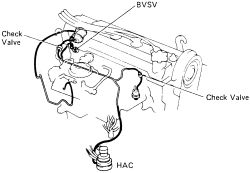

See Figures 1 and 2

The spark control system is used to reduce the NOx and HC emissions. The system serves to delay the vacuum advance for a given time, while also lowering the maximum combustion temperature.

|  |

Fig. Fig. 1: Spark Control (SC) system components-except California models

|  |

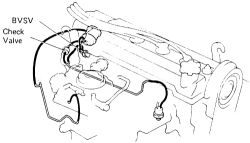

Fig. Fig. 2: Spark control system components used on California models

TESTING Vacuum Advancer

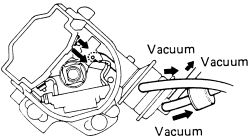

See Figure 3

- Remove the distributor cap and rotor.

- Apply vacuum to the retard diaphragm, then the advance diaphragm. Check that the vacuum advancer moves in accordance with the vacuum.

|  |

Fig. Fig. 3: Check the vacuum advance mechanism for movement when vacuum is applied

- If a problem is found, replace the vacuum advancer. Install the cap and rotor.

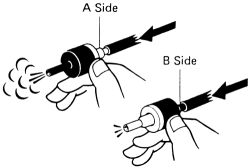

See Figure 4

- Check that air flows from side A of the valve to side B.

|  |

Fig. Fig. 4: Air should flow from side A to B, but not from side B to A

- Check that air does not flow from side B to side A. If the valve is not in working order, replace it.

- Drain the coolant from the radiator into a suitable container.

- Remove the BVSV.

- Cool the BVSV in water below 104°F (40° C).

- Blow air into a pipe and check that the BVSV is closed.

- Heat the valve in water above 129° F (54° C).

- Blow air into the pipe and check that the valve is open.

- Apply liquid sealer to the first few threads of the valve and reinstall it in the engine.

- Fill the radiator with coolant and water mixture. Start the engine and check for leaks.

- If a problem is found with the testing of the BVSV, replace the valve.