OPERATION

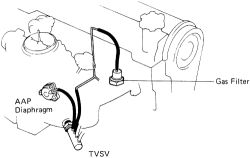

See Figure 1

To reduce emissions, carburetor air/fuel mixtures are calibrated to be as lean as possible. Although a lean mixture will burn readily at hotter temperatures, it is reluctant to ignite when cold because fuel vaporizes less readily when cold. Thus, increasing the amount of fuel in a cold air/fuel mixture increases the amount of vaporized fuel available.

|  |

Fig. Fig. 1: Auxiliary Acceleration Pump (AAP) system components-4A-GE engine shown, others similar

The problem of a poor air/vaporized fuel mixture in a cold engine is accentuated when accelerating. Although the carburetor is equipped with an acceleration pump for the normal demands of an accelerating engine, its capacity is insufficient for a cold engine. The Auxiliary Acceleration Pump (AAP) is designed to send additional fuel into the acceleration nozzle in the carburetor independent of the regular acceleration pump.

The AAP itself is an integral part of the carburetor. It consists of two check valves controlled by springs and a diaphragm controlled by both a spring and engine vacuum. At constant speeds, intake manifold vacuum draws the AAP diaphragm back, enlarging the chamber and allowing gasoline to enter. When the engine is accelerated, intake manifold vacuum drops, allowing the AAP diaphragm to be pushed back by the spring. The resultant reduction in chamber volume forces the gasoline out through the other check valve, into the acceleration nozzle.

AAP operation is governed by the same switching valve used in the choke breaker system. At cold coolant temperatures, the valve allows intake manifold vacuum to reach the AAP diaphragm. At approximately 131°F (55°C), it closes off the passage to vacuum, thus shutting off the AAP function on a fully warmed engine.

INSPECTION

The vacuum hose should be checked for leaks, kinks, or improper connection.

- With the engine cold and idling, remove the air cleaner cap and look into the carburetor.

- Pinch the AAP hose shut and stop the engine.

- Release the hose; check that a spurt of gas is seen from the acceleration nozzle at the instant the vacuum hose is released.

- Fully warm the engine to normal temperature and repeat the test.

- No gasoline should spurt from the acceleration nozzle.

- Reinstall the air cleaner.