OPERATION

See Figure 1

This system only applies to the 4A-F engine.

This system cuts off part of the fuel in the slow circuit of the carburetor to prevent overheating and afterburning of the exhaust system.

|  |

Fig. Fig. 1: Deceleration fuel cut system components

TESTING

See Figures 2 and 3

- Connect a tachometer to the engine.

- Start the engine and check that it runs normally.

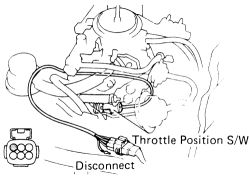

- Disconnect the throttle position switch terminal.

|  |

Fig. Fig. 2: Disconnect the throttle position switch wire from the harness

- Gradually increase the engine speed to 2300 rpm. Check that the engine slightly fluctuates.

WARNING

Perform this procedure quickly to avoid overheating the catalytic converter.

- Reconnect the throttle position switch terminal. Again gradually increase the engine speed to 2300 rpm. and check that the engine operation is normal.

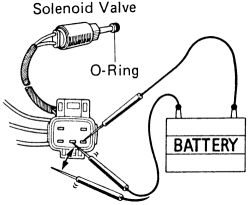

- With the engine at idle unplug the solenoid valve. Connect two terminals and the battery terminals as shown.

|  |

Fig. Fig. 3: Connect the two terminals of the solenoid to the battery

- Check for a click in the solenoid valve when the battery is connected and disconnected.

- Check the O-ring for damages.

- Reinstall the valves and reattach the wiring.

REMOVAL & INSTALLATION Fuel Cut Solenoid Valve

This solenoid valve is only applicable to the 4A-F carbureted engines.

- Disconnect the solenoid valve wiring.

- Carefully unscrew the valve from the carburetor. Discard the old O-ring.

- Place a new O-ring on the end of the valve and securely tighten the unit into the carburetor.