REMOVAL & INSTALLATION

See Figure 1

- Park the vehicle on a level surface.

- Remove the jack, tire iron and, if necessary, the spare tire from their storage compartments.

- Check the owner's guide or refer to of this repair guide for the jacking points on your vehicle. Then, place the jack in the proper position.

- If equipped with lug nut trim caps, remove them by either unscrewing or pulling them off the lug nuts, as appropriate. Consult the owner's guide, if necessary.

- If equipped with a wheel cover or hub cap, insert the tapered end of the tire iron in the groove and pry off the cover.

- Apply the parking brake and block the diagonally opposite wheel with a wheel chock or two.

Wheel chocks may be purchased at your local auto parts store, or a block of wood cut into wedges may be used. If possible, keep one or two of the chocks in your tire storage compartment, in case any of the tires has to be removed on the side of the road.

- If equipped with an automatic transmission/transaxle, place the selector lever in P or Park; with a manual transmission/transaxle, place the shifter in Reverse.

- With the tires still on the ground, use the tire iron/wrench to break the lug nuts loose.

If a nut is stuck, never use heat to loosen it or damage to the wheel and bearings may occur. If the nuts are seized, one or two heavy hammer blows directly on the end of the bolt usually loosens the rust. Be careful, as continued pounding will likely damage the brake drum or rotor.

- Using the jack, raise the vehicle until the tire is clear of the ground. Support the vehicle safely using jackstands.

- Remove the lug nuts, then remove the tire and wheel assembly.

- Make sure the wheel and hub mating surfaces, as well as the wheel lug studs, are clean and free of all foreign material. Always remove rust from the wheel mounting surface and the brake rotor or drum. Failure to do so may cause the lug nuts to loosen in service.

- Install the tire and wheel assembly and hand-tighten the lug nuts.

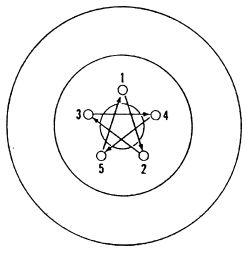

- Using the tire wrench, tighten all the lug nuts, in a criss-cross pattern, until they are snug.

- Raise the vehicle and withdraw the jackstand, then lower the vehicle.

- Using a torque wrench, tighten the lug nuts in a criss-cross pattern to 76 ft. lbs. (103 Nm). Check your owner's guide or refer to of this repair guide for the proper tightening sequence.

|  |

Fig. Fig. 1: Typical wheel lug tightening sequence

WARNING

Do not overtighten the lug nuts, as this may cause the wheel studs to stretch or the brake disc (rotor) to warp.

- If so equipped, install the wheel cover or hub cap. Make sure the valve stem protrudes through the proper opening before tapping the wheel cover into position.

- If equipped, install the lug nut trim caps by pushing them or screwing them on, as applicable.

- Remove the jack from under the vehicle, and place the jack and tire iron/wrench in their storage compartments. Remove the wheel chock(s).

- If you have removed a flat or damaged tire, place it in the storage compartment of the vehicle and take it to your local repair station to have it fixed or replaced as soon as possible.

INSPECTION

Inspect the tires for lacerations, puncture marks, nails and other sharp objects. Repair or replace as necessary. Also check the tires for treadwear and air pressure as outlined in of this repair guide.

Check the wheel assemblies for dents, cracks, rust and metal fatigue. Repair or replace as necessary.