REMOVAL & INSTALLATION

- Raise and support the vehicle safely.

- Remove the front wheels.

- Disconnect the brake hose and 2 gaskets from the caliper. Plug the end of the hose to prevent loss of fluid.

- Remove the bolts that attach the caliper to the torque plate.

- Lift up and remove the brake caliper assembly.

- Installation is the reverse of the removal procedure. Always use NEW gaskets for the brake hose. Grease the brake caliper slides and bolts with Lithium grease or equivalent. Install and tighten the caliper mounting bolts to 18 ft. lbs. (25 Nm) on 1990-92 vehicles and 25 ft. lbs. (34 Nm) on the 1993 vehicle. Fill and bleed the system. Before moving the vehicle, make sure to pump the brake pedal a few times to seat the pads against the rotors.

OVERHAUL

See Figures 1 through 8

Some vehicles may be equipped dual piston calipers. The procedure to overhaul the caliper is essentially the same with the exception of multiple pistons, O-rings and dust boots.

- Remove the caliper from the vehicle and place on a clean workbench.

Depending upon the vehicle, there are two different ways to remove the piston from the caliper. Refer to the brake pad replacement procedure to make sure you have the correct procedure for your vehicle.

-

The first method is as follows:

- Stuff a shop towel or a block of wood into the caliper to catch the piston.

- Remove the caliper piston using compressed air applied into the caliper inlet hole. Inspect the piston for scoring, nicks, corrosion and/or worn or damaged chrome plating. The piston must be replaced if any of these conditions are found.

|  |

Fig. Fig. 1: For some types of calipers, use compressed air to drive the piston out of the caliper, but make sure to keep your fingers clear

|  |

Fig. Fig. 2: Withdraw the piston from the caliper bore

- For the second method, you must rotate the piston to retract it from the caliper.

- If equipped, remove the anti-rattle clip.

|  |

Fig. Fig. 3: On some vehicles, you must remove the anti-rattle clip

- Use a prytool to remove the caliper boot, being careful not to scratch the housing bore.

|  |

Fig. Fig. 4: Use a prytool to carefully pry around the edge of the boot ...

|  |

Fig. Fig. 5: ... then remove the boot from the caliper housing, taking care not to score or damage the bore

- Remove the piston seals from the groove in the caliper bore.

|  |

Fig. Fig. 6: Use extreme caution when removing the piston seal; DO NOT scratch the caliper bore

- Carefully loosen the brake bleeder valve cap and valve from the caliper housing.

- Inspect the caliper bores, pistons and mounting threads for scoring or excessive wear.

- Use crocus cloth to polish out light corrosion from the piston and bore.

- Clean all parts with denatured alcohol and dry with compressed air.

- Lubricate and install the bleeder valve and cap.

- Install the new seals into the caliper bore grooves, making sure they are not twisted.

- Lubricate the piston bore.

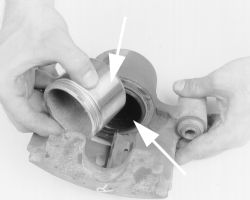

- Install the pistons and boots into the bores of the calipers and push to the bottom of the bores.

- Use a suitable driving tool to seat the boots in the housing.

|  |

Fig. Fig. 7: Use the proper size driving tool and a mallet to properly seal the boots in the caliper housing

- Install the caliper in the vehicle.

- Install the wheel and tire assembly, then carefully lower the vehicle.

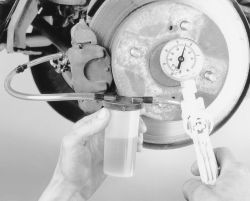

- Properly bleed the brake system.

|  |

Fig. Fig. 8: There are tools, such as this Mighty-Vac, available to assist in proper brake system bleeding

- Pump the brake pedal a few times, and check the brake system for leaks.