Metal lines and rubber brake hoses should be checked frequently for leaks and external damage. Metal lines are particularly prone to crushing and kinking under the vehicle. Any such deformation can restrict the proper flow of fluid and therefore impair braking at the wheels. Rubber hoses should be checked for cracking or scraping; such damage can create a weak spot in the hose and it could fail under pressure.

Any time the lines are removed or disconnected, extreme cleanliness must be observed. Clean all joints and connections before disassembly (use a stiff bristle brush and clean brake fluid); be sure to plug the lines and ports as soon as they are opened. New lines and hoses should be flushed clean with brake fluid before installation to remove any contamination.

REMOVAL & INSTALLATION

See Figures 1 through 6

- Disconnect the negative battery cable.

- Raise and safely support the vehicle on jackstands.

- Remove any wheel and tire assemblies necessary for access to the particular line you are removing.

- Thoroughly clean the surrounding area at the joints to be disconnected.

|  |

Fig. Fig. 1: Use a brush to clean the fittings of any debris

- Place a suitable catch pan under the joint to be disconnected.

- Using two wrenches (one to hold the joint and one to turn the fitting), disconnect the hose or line to be replaced.

|  |

Fig. Fig. 2: Use two wrenches to loosen the fitting. If available, use flare nut type wrenches

- Disconnect the other end of the line or hose, moving the drain pan if necessary. Always use a back-up wrench to avoid damaging the fitting.

- Disconnect any retaining clips or brackets holding the line and remove the line from the vehicle.

If the brake system is to remain open for more time than it takes to swap lines, tape or plug each remaining clip and port to keep contaminants out and fluid in.

|  |

Fig. Fig. 3: Any gaskets/crush washers should be replaced with new ones during installation

|  |

Fig. Fig. 4: Tape or plug the line to prevent contamination

- Install the new line or hose, starting with the end farthest from the master cylinder. Connect the other end, then confirm that both fittings are correctly threaded and turn smoothly using finger pressure. Make sure the new line will not rub against any other part. Brake lines must be at least 1/2 in. (13mm) from the steering column and other moving parts. Any protective shielding or insulators must be reinstalled in the original location.

- Using two wrenches as before, tighten each fitting.

- Install any retaining clips or brackets on the lines.

- If removed, install the wheel and tire assemblies, then carefully lower the vehicle to the ground.

- Refill the brake master cylinder reservoir with clean, fresh brake fluid, meeting DOT 3 specifications. Properly bleed the brake system.

- Connect the negative battery cable.

|  |

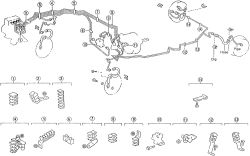

Fig. Fig. 5: Brake line routing on non-ABS systems

|  |

Fig. Fig. 6: ABS brake line routing